We have explained our ideas and practices on sustainable fashion business model in #metaverse which is far more grand and diverse than the real world. Next, we would like to add a supplement opinion. What preconditions, preparations and integration methods are necessary to realize such a business model?

First of all, we clearly understand that to realize sustainable fashion in the physical world, the root solution is avoiding producing physical waste in every link. And the essential method is producing according to sales through #design and pattern making management.

Because metaverse breaks all kinds of physical boundaries and restrictions in real life, people can freely switch the clothes that only exist in the virtual world or the clothes that can be worn both in the real world and virtual world. Then, the part that may generate waste is the sales of physical clothes that also exist in metaverse.

Therefore, to avoid return and even disuse of clothes because of the big gap between the physical ones and virtual appearances, the technology that can be integrated into the metaverse is not simple imagine matching. It must be Digital-Twin Matching which can also confirm fit & size of the clothes.

For example, as for the well-known automatic driving and smart city, the integration of any industry with the metaverse will adopt the most appropriate integration mode according to the respective characteristics and target scenarios of the industry. However, no matter VR, AR or MR is used, it must undergo reality simulation, virtual modeling and digital management. For fashion industry, there is no exception.

Physical→PHGITAL→Digital, These are necessary routes.

1. Physical Digital fashion, the digital fashion which informs the way we produce physical fashion. The product therefore is physical.

2. Phygital fashion, physical and digital combined. The product is digital fashion that can be worn by humans.

3. Fully Digital fashion, sold direct to avatar.

Over the past 15 years, SdibiT has been aiming for the Phygital fashion, mastered the full methodology and know-how of the integration process.

1.Vhuman database establishment;

2. 3D clothing digital design pattern database based on Vhuman;

3. Interchangeable application based on digital modular management;

4. The integration of digital fabrics and designs has also been tested.

The preparation work has already been finished. Just like Bingo Game, we have arrived at the point waiting for the fifth one.

In the video, both images are about changing clothes, one is dazzling, the other is plain.

However, the essential difference is that SdibiT can ensure that whether the end consumer wear the clothes on his 3DAvatar or physical body, the general looking and fit&size effect are the same.

In fact, with the data and technology accumulation held by SdibiT, millions of different sets of clothing that can be worn in both virtual and real world can be generated. Limited by current platform(software&hardware), it cannot be visualized completely and adequately(to be explained later).

Now, we talk about fabric, one of the three major elements of clothing as people, design&pattern.

At present, the reality is that from the perspective of color and graphic, most fabric manufacturers rely on fashion prediction to develop and produce products. Ready-to-wear fashion designers only can do designs using fabric samples sent from fabric manufacturers, also relying on prediction of consumer demand. Following these steps, designers can not completely understand and respond to the real demands of end consumers. Each country, region and brand will also have different information because of their own policies. We believe that the waste and environmental problems caused by repeated procurement, repeated R&D and prediction errors need to be solved as soon as possible from the perspective of raw material resource allocation of fabrics. As mentioned before, if the Eco-friendly fabric with hard-working of R&D are not sold and turned into inventory, finally can only be discarded, is it contrary to the original intention of environmental protection?

Apart from the fabrics that must be dyed first in the process, we will talk about the solution for fabrics which can be printed or dyed with colors and graphics after weaving. And this solution can be put into use immediately.

Imagine the following scenario. The original white textiles before printing and dyeing made from materials bio or marine-degradable are allocated reasonably at cooperative factories around the world. After receiving the order from the end consumer, the system recognizes the delivery address, appoints the nearest factory that can print and produce according to consumer’s requirements to finish the order. Thus, the delivery logistic is the shortest distance.

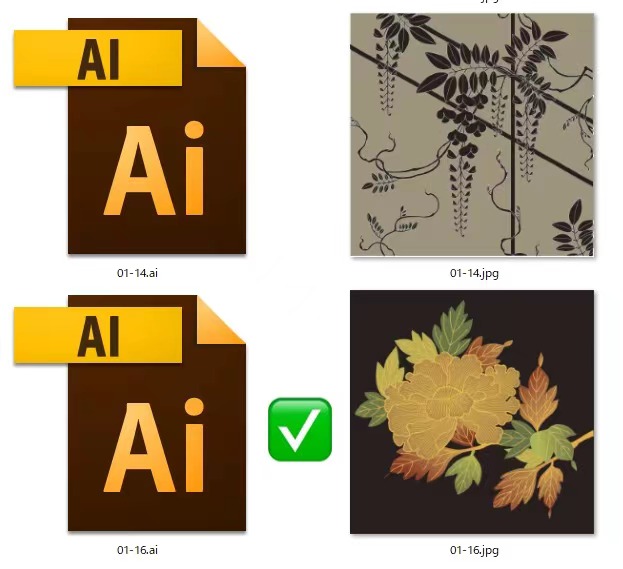

As shown in the picture, SdibiT has completed the integration test of #digital fabric and design. Although the number is small, we insist in involving consumers into #design process and delivering goods in this way. We are looking forward to cooperate with more partners to deepen our practice in the real world while exploring the feasible solution in #metaverse.

While the Metaverse brings new production and consumption processes, it will also cause changes in perceptions of reality and demands. Therefore, it is expected that the sustainable development of the textile industry will be accelerated.

2nd Sep,2022