Clients who get to understand our solution for the first time often have the following response. “Ah, comparing #CLO, #Browzwear, #Optitex, #Style3D, etc, your DX solution is in the reverse order.” And I would say every time that we did not deliberately reverse, our solution just correct the process to the right track❗️

Let’s think about it together. The clothing making process 150 years ago, is just like the modern haute couture customization process. Each piece is made based on the customer’s body and confirm the right fit&size, then the 3D prototype obtained on the real body is converted into drawings of 2D pattern, being sewed finally.

In the era of industrial high-speed mass production, the process gradually deviated from the original route due to time, efficiency and cost, and the most important reason, there was no 3D digital design tools.

Strictly speaking, from the perspective of other industries such as architecture, shipbuilding, etc., #design drawings and 2D processing drawings are different things❗️

2D pattern maker’s job is not creating design drawings but generating CAM data for execution of processing output.

The popularity of 2D pattern making software in the era of mass production is because it enabled efficient management of the CAM data used in production line processing.

With the development of #digital technology, high efficiency, precision and low cost can be achieved simultaneously while the steps are corrected back into the logically right order.

Let’s think further more together. If one customer likes the design draft generated by AI and decides to buy, the seller just need to make the physical clothing faithfully restore the design while ensuring the right fit&size of the customer.

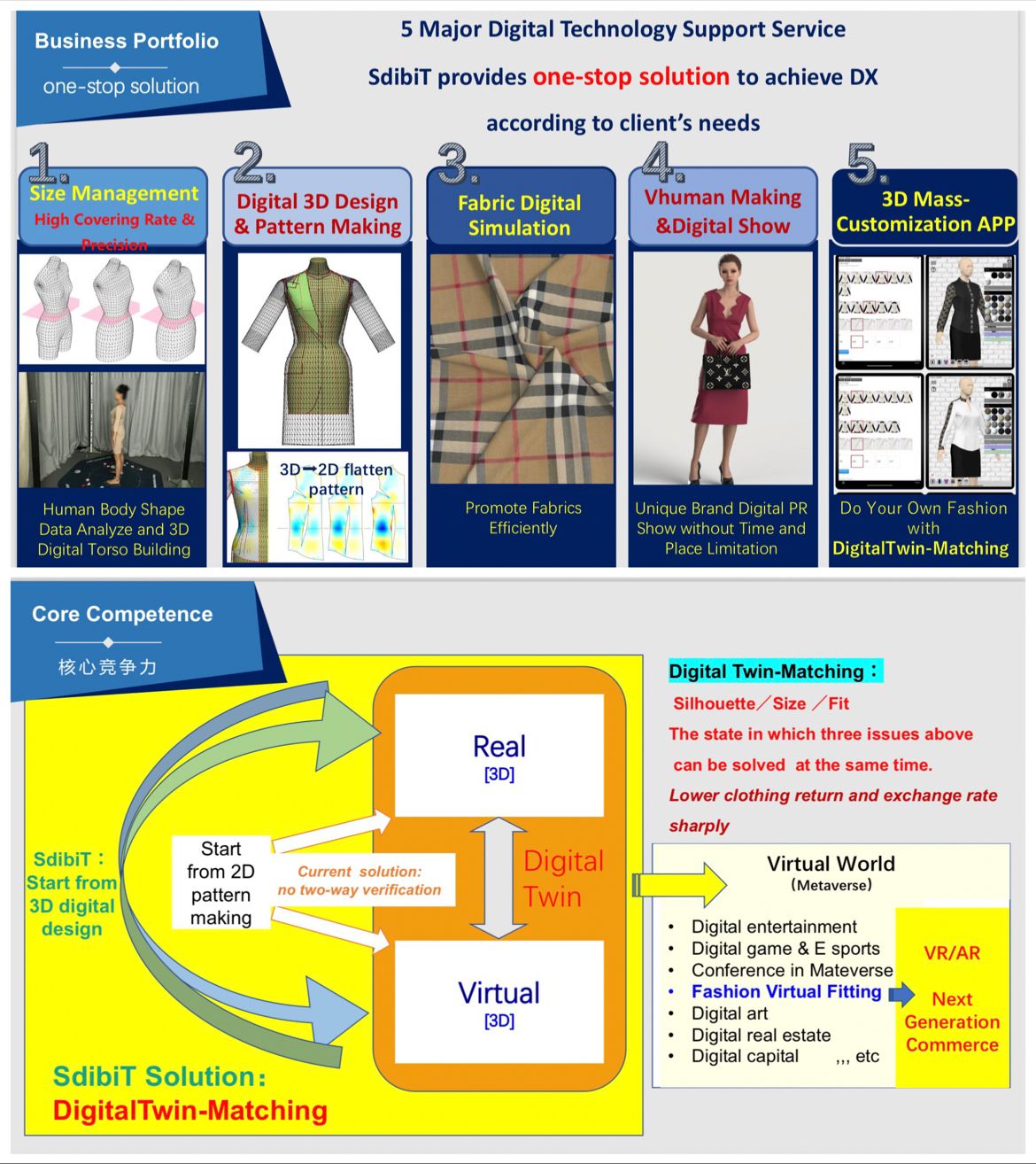

The core advantage of our solution is the ability to quickly convert designs into production pattern and achieving DigitalTwin-Matching at the same time. After this, the job can be done easily. Just sew the specified fabric according to the pattern.

So here comes the problem. At present, the pattern generated by 2Dcad is first used for 3D modeling and then be sent to the customer for confirmation. If we receive modification requirement, we have to get back to 2D pattern to do modifications. Except for some simple basic styles, will this kind of workflow definitely put the 2D pattern makers into hysteria❓

The workload do not decrease but increase because they have to use the modeling and rendering software to make 3D views of patterns they made and send to customers for confirmation repeatedly. What’s more, this kind of display only shows the appearance of the garment, it does not show the Fit&Size state at the same time…

(to be continued…)

27th.Feb,2023