We believe that, roughly speaking, there are two major characteristics that distinguish human beings from other animals. The first is that human beings take the initiative to wear clothes to cover the body. The basic function of clothes is protecting the body. However, people like to wear different beautiful clothes for vision pleasure and self-expression. The clothes become a symbol to distinguish one person from another. The second characteristic is that human beings can create and use tools actively to achieve their own goals.

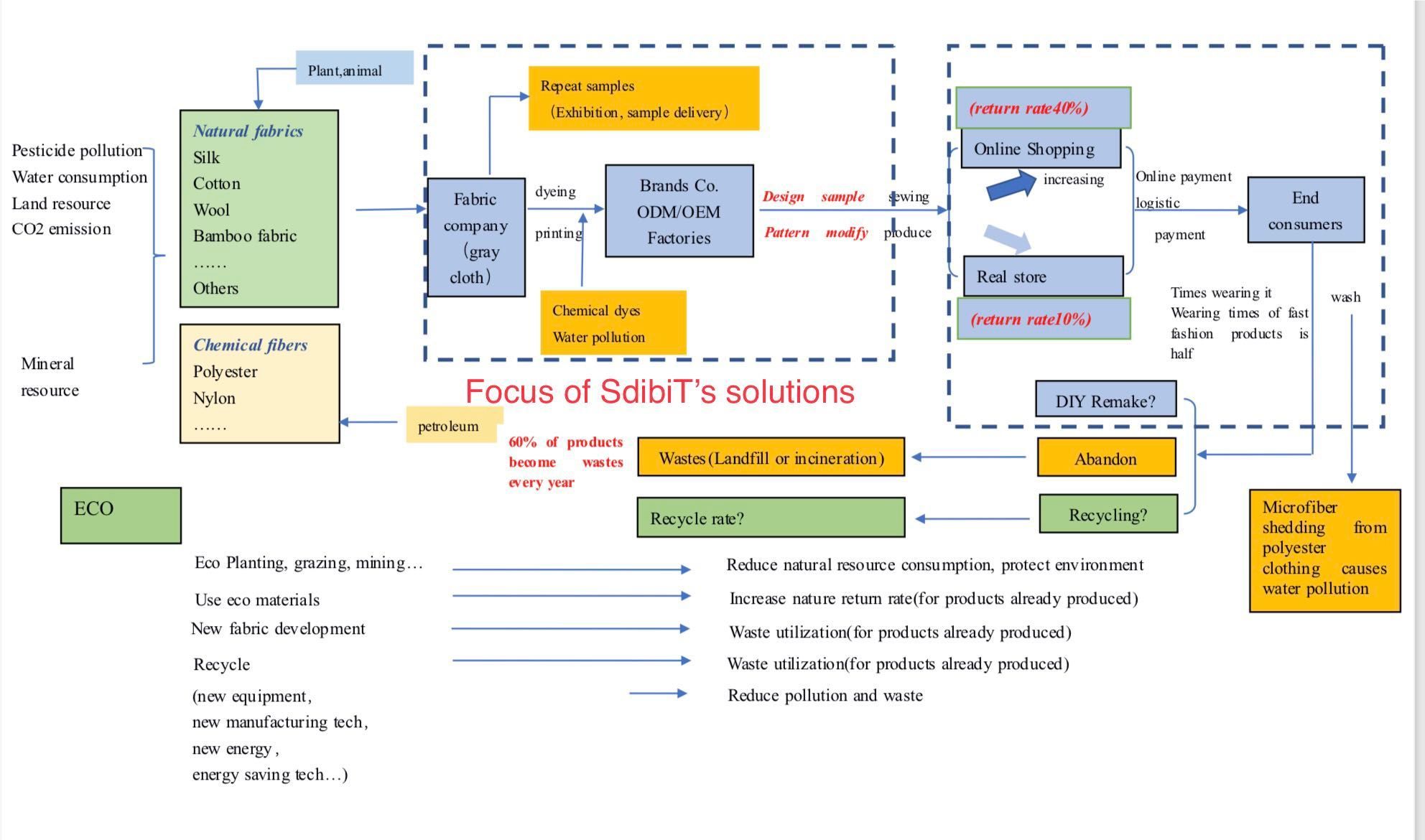

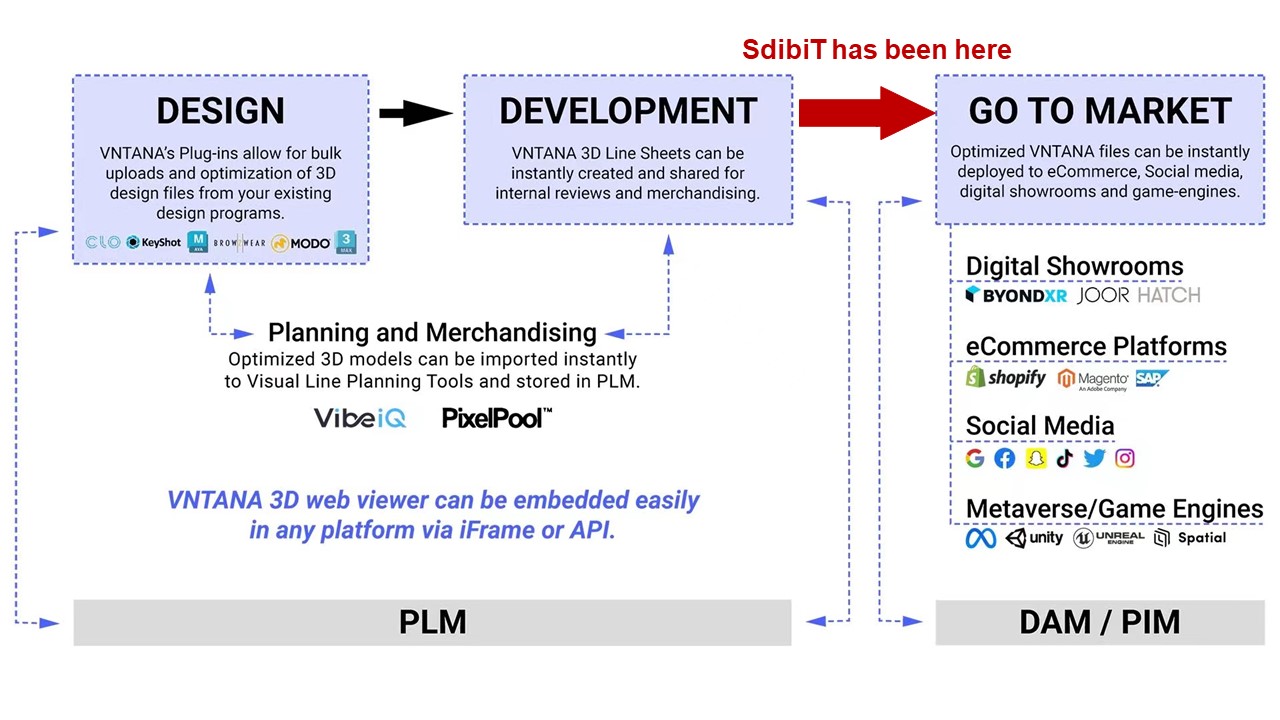

When people realize that the metaverse, which is much broader and diverse than the real world, is rapidly opening, they will definitely create or use various digital tools to generate more new forms of products in the new application scenarios to satisfy their spiritual needs. Looking at humans’ feature of wearing clothes, the traditional manufacturing process of clothing is at the expense of environmental pollution, and people have formed an unprecedented consensus that the earth is overwhelmed. We believe that the sustainable fashion business model in the metaverse will soon be divided into two types in the next few years.

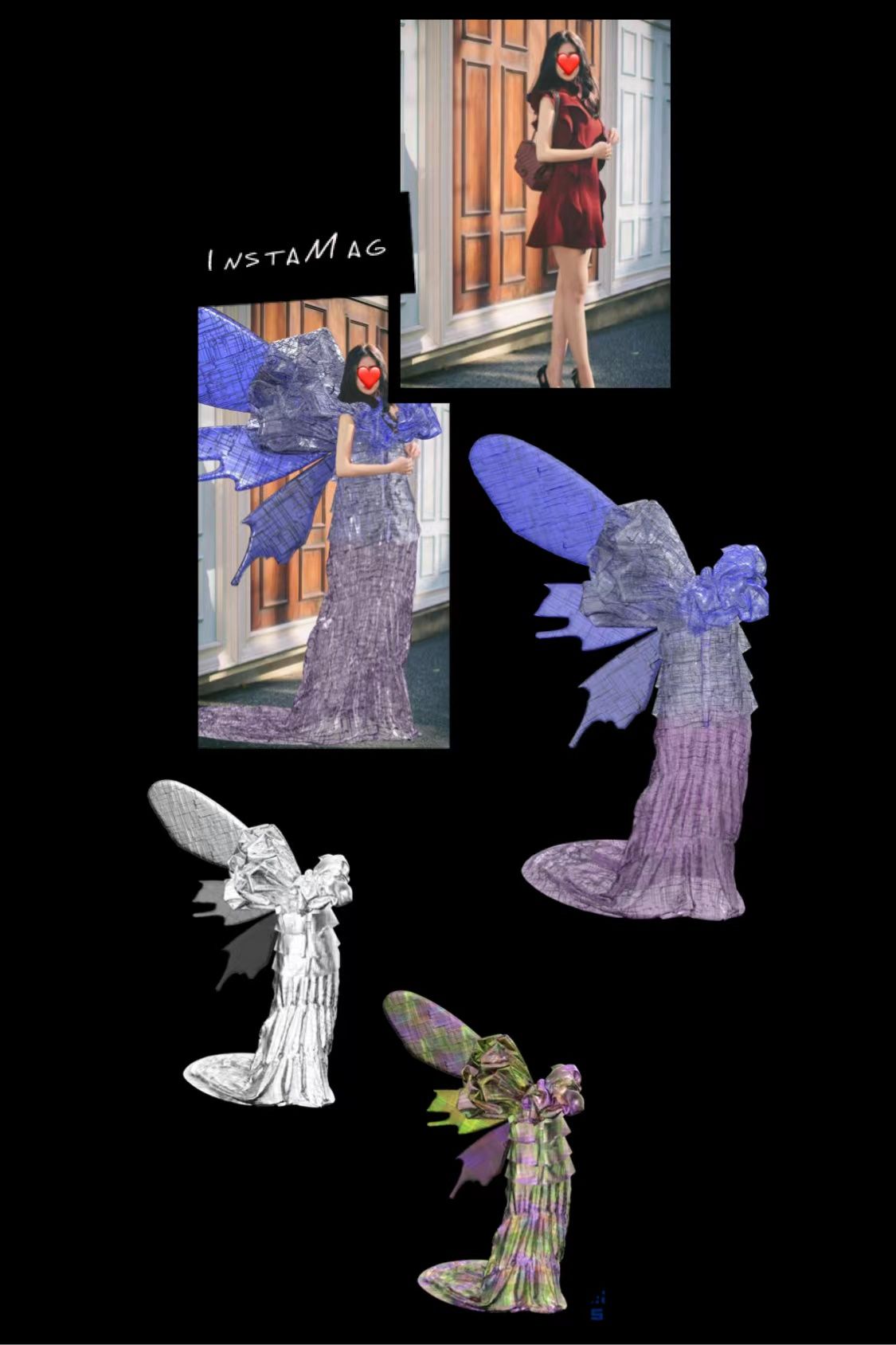

First, if the purpose is only for vision pleasure or social contact in the virtual world, people will be willing to accept that clothes are presented in digital form, only exist in the virtual world, and do not need to be converted into physical objects. This kind of digital clothing supply can reduce the material waste and relieve environmental burden caused by pure whim. Fashion NFT works, character costumes in 3D animation or game, avatar’s dressing in metaverse, etc. will replace part of physical clothes and become more and more popular for entertainment or spiritual satisfaction.

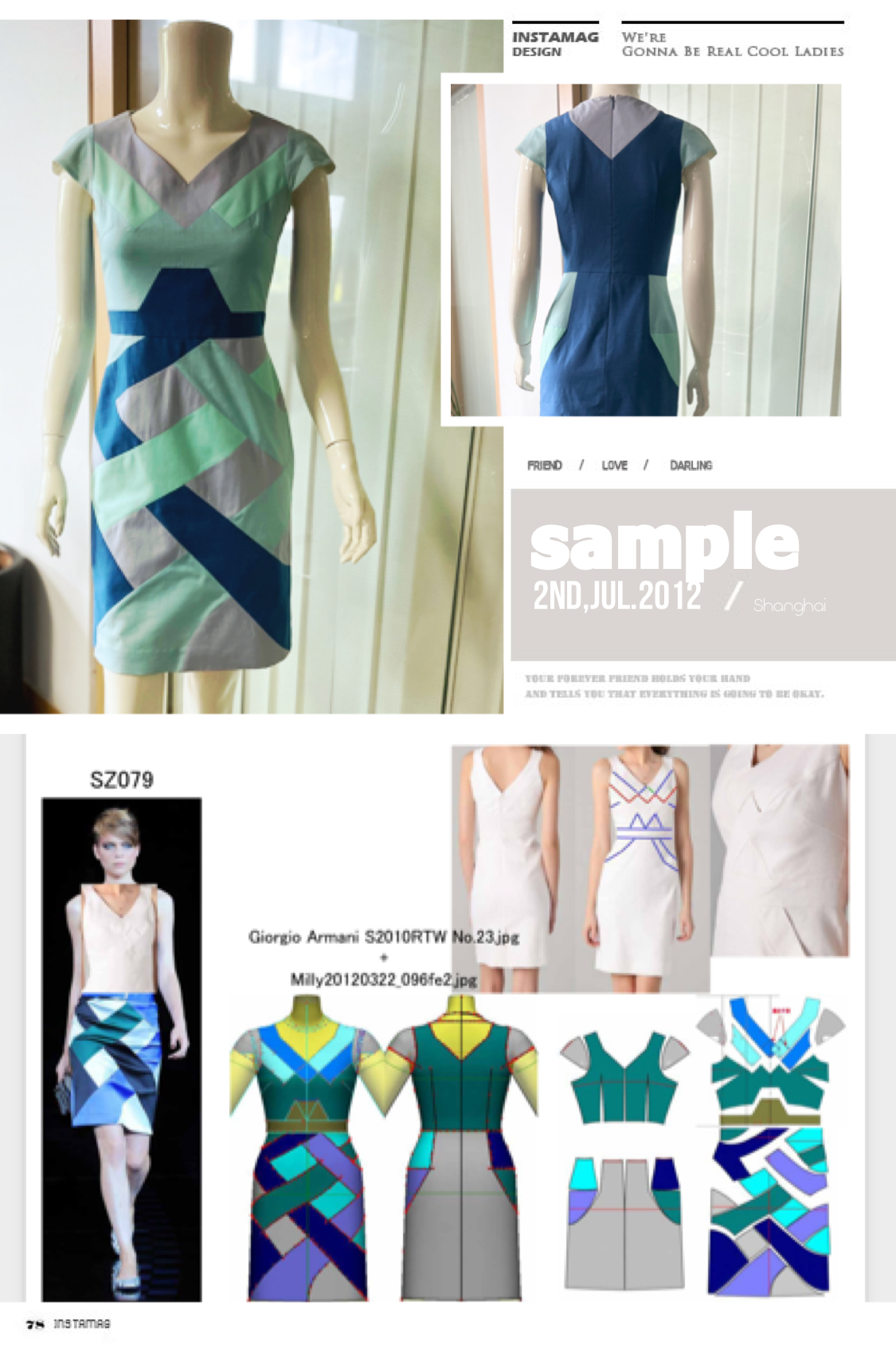

The second is to develop and use digital tools to meet individual needs conveniently in the environment friendly way. From the perspective of convenience, people can do shopping without time and space limitation, confirm the wearing effect in a virtual state. From the perspective of environmental sustainability, people will increasingly tend to choose clothing that can faithfully restore the virtual effects they once recognized. The greatest satisfaction of people is that the service of this kind of digital clothing fully matches their personalized needs.

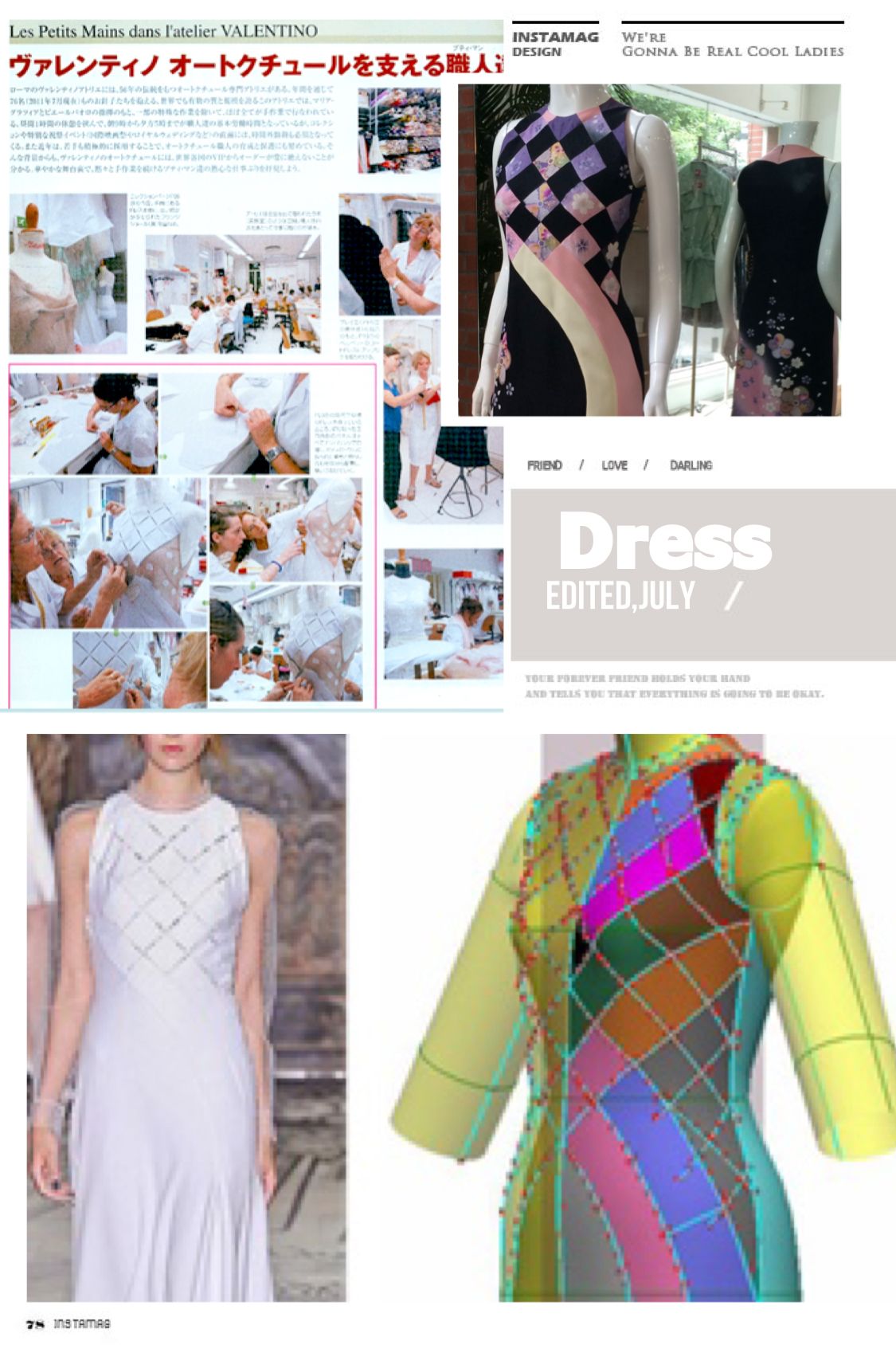

Imagine such a scenario. Everyone can have several Avatars of different styles in metaverse. One Avatar of them is originated from real body scanning shape data of the user. It can be called 3D Human Avatar.

A female X may visit a clothing store in metaverse using her animation Avatar, crush on a certain garment that VHuman Avatar(virtual influencer) wearing. She can change into her 3D human Avatar and do virtual try-on fitting.

She likes it and decides to buy for her 3D human Avatar. Then this 3D human Avatar wearing on new garment continues to party with friends in the metaverse. Everywhere she goes, she is praised by everyone for her dressing style, and X has the desire to wear the same physical clothes to the business dinner in the real world.

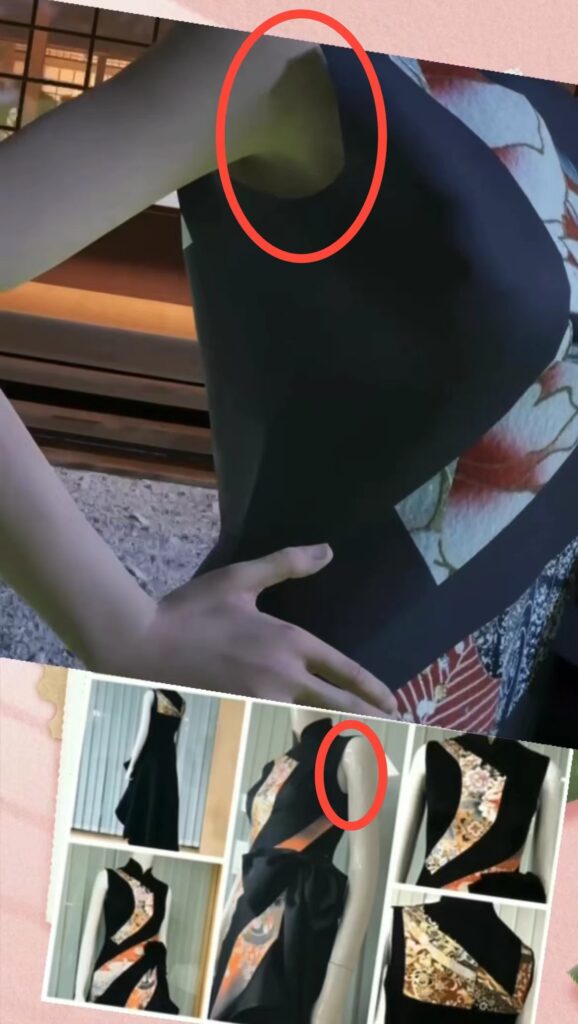

So X places an order in the metaverse store, and the dress is directly sent to the hotel reception of her business dinner. The store in the metaverse will submit the image data of this dress to X’s personal wardrobe in the metaverse, which is convenient for her to retrieve and match with other virtual clothes from any other metaverse store . And because X has already paid for the same digital clothing, she can enjoy a discount or favorable price deducts the digital price for the physical dress, so X will be really happy with her double harvest. One week later, X arrives at the hotel and puts on the dress. The wearing effect is just the same as the virtual fitting in the metaverse. X looks gorgeous and has a pleasant meal with the client. The supply of this type of digital clothing cannot be achieved by the simple image matching type of digital clothing. In other words, it must be able to switch between the virtual and the real, including fit & size.

The prerequisite, of course, is to achieve a direct digital twin to the end consumer.

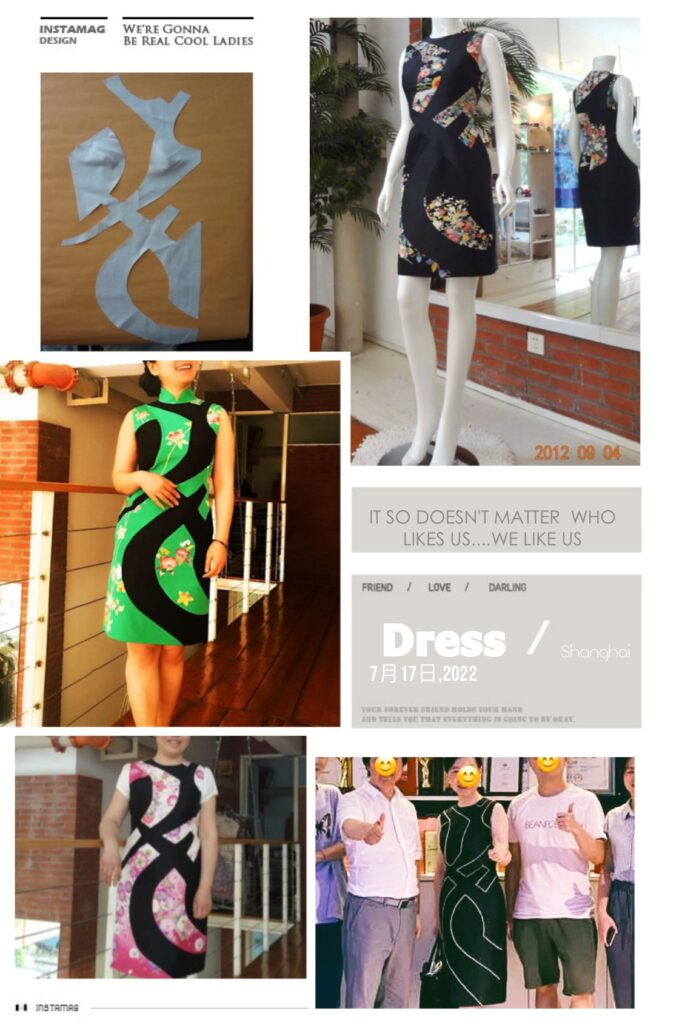

In fact, we already have experienced similar cases during our business practice in China 10 years ago. A female entrepreneur was too busy to have time go shopping for dress. She often asked us to provide photos of products which the style she likes and made selections. Then we packed the dress of her size and gave it to her driver. The driver often sent the dress directly to the hotel she stayed in Beijing. What we are proud of is that this customer has never returned or exchanged goods because of the wrong size.

Sdibit expects to provide more scalable services to customers of more brands. For example, a Chinese girl X likes a dress from a Japanese merchant online, confirms online virtual fitting effect, places an order and informs the merchant that she will travel to Italy, hoping to receive the dress in Italy. The merchant immediately transmits the design pattern and fabric data of the dress to the cooperative plant in Italy to start production. A week later, when X arrives Italy, she can be satisfied to wear the dress she ordered , save time and energy for pleasant sightseeing.

With the continuous improvement of hardware and software and the continuous accumulation of know-how, we believe that within the next 3-5 years, business model vision in the metaverse scenario will be realized one by one.

29th,Aug.2022