生地の色柄が毎年違うだけ..と不満を感じたことのある人は是非お読みください

This article is specially for people who are not satisfied with changes limited in fabric colors and patterns.

The way to generate 2D patterns that addresses Fit&Size Issues is very different from the traditional way of making clothes today.

First, create a 3D prototype with a silhouette that ensures comfort.

Second, create 3D Garment Models according to different requirements from customers or different sizes. Then generate 2D patterns.

Using our company’s method, it takes more than 3 times working hour to make 2D patterns corresponding to #DigitalTwinMatching.

That is to say, it is much more difficult to make patterns achieving good Fit&Size.

At the end of last year, we accomplished a job of making garment 2D patterns which realizes DigitalTwin-Matching according to designated design drawings. This is the most difficult job so far and it charges more than $12,000 for 1 Look& 1 Size considering time and labor cost.

Brands that can bear such high pattern making cost are limited in #luxury brands like Louis Vuitton, CHANEL, Valentino, Versace, etc.

Then how the ordinary ready-to-wear business balance such high design and pattern making cost with revenue?

Learn from other manufacturing industries.

1. Maximize the use frequency of universal design:

Reuse 3D designs or 2D patterns that have already been developed, and increase production volume by using a 3D design developed once for multiple items.

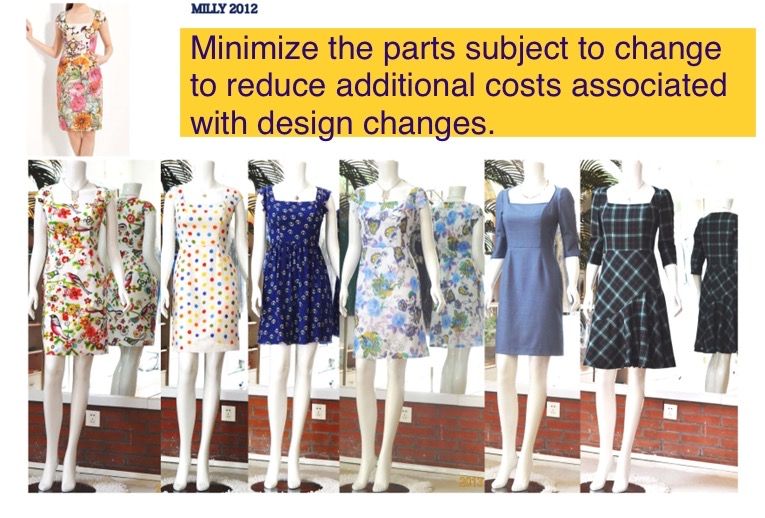

2. Minimize design changes:

Minimize the parts subject to change to reduce additional costs associated with design changes.

In other words, standardize the design.

Secondly, in the fashion design section, turn the priority work from making 2D patterns to management of component design list.

At present, the traditional working mode is that the design section starts from scratch to operate according to different specifications every time. Data information is isolated and fragmented, resulting in a great waste of repetitive time and labor.

Working mode of the design section needs to shift from “centered on design /making 2D patterns” to “centered on BOM(Bill of Materials) management “.

It’s not the standardization of work.

It’s about regularizing the design.

Promote modularization while meeting the specific requirements of different customers.

Matching and combining modular design parts is our Mix&Match-Technology solution.

Here is a cost comparison list.

If the current design cost of 1 look is 100.

Adopting our solution, the cost of 1 look would be 300.

But if you reuse the design with modular management for 10 times and make 10% design fine adjustment every time, then the cost would be 300+ 30×10 =600, and 600/11 is less than 60.

Modular design of best-selling products can greatly reduce the cost and help ordinary ready-to-wear brands achieve high design level as top brands.

8th, March